Heat Pump:

Sri Pumps' range of Heat Pump Water Heaters are designed to meet the stringent thermal requirements of modern industries, combining eco-conscious technology with high-performance engineering. These systems utilize renewable heat sources to deliver energy-efficient heating, ideal for dehydration, cleaning-in-place (CIP), pasteurization, and ambient water heating processes across a variety of sectors.Sri Pumps' range of Heat Pump Water Heaters are designed to meet the stringent thermal requirements of modern industries, combining eco-conscious technology with high-performance engineering. These systems utilize renewable heat sources to deliver energy-efficient heating, ideal for dehydration, cleaning-in-place (CIP), pasteurization, and ambient water heating processes across a variety of sectors. By leveraging advanced refrigeration cycles and precision control mechanisms, our heat pumps ensure consistent output temperatures while significantly reducing energy consumption and operational costs. With stainless steel construction, intelligent thermostats, and compatibility with solar or grid power, they provide a sustainable solution for sectors including dairy, food processing, pharmaceuticals, and chemical industries—where hygiene, reliability, and performance are critical.

Heat Pump Wroking:

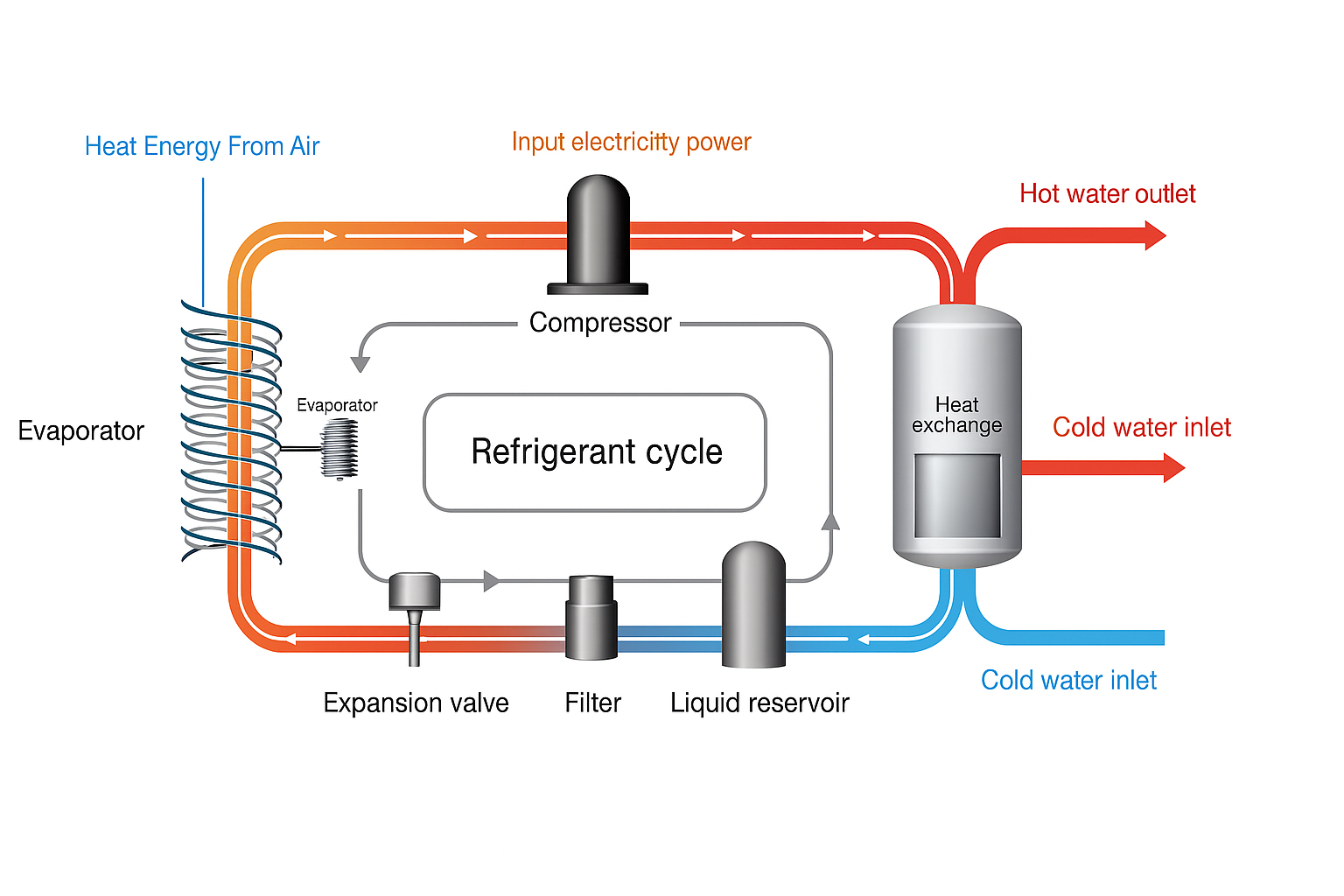

A brine solution (or antifreeze fluid) circulates in a collector loop, where it absorbs thermal energy from external sources such as bedrock, soil, groundwater, air, or surface water. This low-temperature energy is harvested even during cold seasons, making it ideal for year-round use. This tepid brine then passes through a heat exchanger (evaporator), where it comes in contact with a refrigerant circulating in a closed refrigerant loop. The refrigerant, having a low boiling point, absorbs this thermal energy, causing it to evaporate and turn into a gaseous state. The gas is then compressed in a compressor, which significantly increases its pressure and temperature. This step elevates the refrigerant to a temperature suitable for practical heating needs—typically between 35°C to 70°C, depending on the application. In a second heat exchanger (condenser), the hot gaseous refrigerant releases its stored heat to the heating circuit—which may include a water tank, CIP system, floor heating, radiators, or industrial dryer coils. During this process, the refrigerant cools down and condenses back into a liquid. Next, the liquid refrigerant passes through an expansion valve, where its pressure is reduced. This causes a drop in temperature, returning the refrigerant to its initial low-energy liquid state. The cycle restarts as the refrigerant re-enters the evaporator to absorb more heat from the brine, creating a continuous and energy-efficient loop.

Applications:

-

Dairy Processing: Heats water for pasteurization, CIP (cleaning-in-place), and fermentation processes.

-

Pharmaceuticals: Maintains strict temperature control for equipment sterilization and hot water needs.

-

Textile Industry: Used in dyeing, drying, and hot water supply for washing processes.

-

Automotive: Supports paint booth temperature regulation and parts washing systems.

-

Chemical Plants: Maintains process water temperature and distillation requirements.

-

Hotels & Resorts: Centralized hot water generation for guest rooms, kitchens, and laundries.

-

Hospitals: Sterile hot water supply for cleaning, sanitation, and patient use.

-

Irrigation Heating: Heats water for controlled irrigation in cold climates.

-

Boiler Feed Pre-heating: Reduces energy load on boilers by supplying pre-heated water.

-

Laundry & Sanitization Units: Powers industrial washing and sanitizing units.

Available Models:

|

HEAT

PUMP – AVAILABLE MODELS

|

||||

| Model | Heating Capacity | Power Supply | Heating Temp. Range | Application |

| HP-3KW | 3 kW | 230V / 50Hz | 25°C – 65°C | Residential & Labs |

| HP-10KW | 10 kW | 400V / 50Hz | 25°C – 75°C | Food & Pharma |

| HP-20KW | 20 kW | 400V / 50Hz | 30°C – 80°C | Agro-Processing |

| HP-50KW | 50 kW | 400V / 50Hz | 35°C – 85°C | Industrial Drying |

| HP-CUSTOM | Custom Config. | On Request | Up to 90°C | OEM Integration |

benefits:

-

Energy Efficient: Up to 75% energy savings vs traditional systems

-

Eco-Friendly: Zero emissions, low noise operation

-

All Weather Use: Suitable for tropical, humid & cold climates

-

Compact Design: Portable options with SS trolley

-

Customizable: Available in both floor-standing & wall-mounted units

-

Smart Control: Digital PID/PLC controllers for precision

-

High ROI: Low maintenance, long lifespan